Among the circle of McLaren, Ferrari, Lamborghini, and AMG, carbon ceramic brakes have emerged as a defining choice. Though their purpose seems simple, their construction represents a level of material science once reserved for aerospace.

By shedding nearly half the mass of conventional steel brakes, manufacturers reduce what engineers call unsprung weight, the portion of a vehicle’s mass not supported by the suspension. Less unsprung mass means faster suspension response, sharper turn-in, and a subtler ride. The result is greater composure, enabling the car to read the road with extraordinary fidelity.

Where repeated high-speed deceleration can drive temperatures well beyond 1,000 degrees Celsius, traditional iron discs would quickly fade or deform. Carbon ceramics thrive in that environment, delivering unwavering performance lap after lap.

Under normal conditions, carbon ceramic brakes can last the lifetime of the vehicle. Their immunity to rust and corrosion translates into lower long-term maintenance costs, a subtle but compelling factor for owners and manufacturers alike.

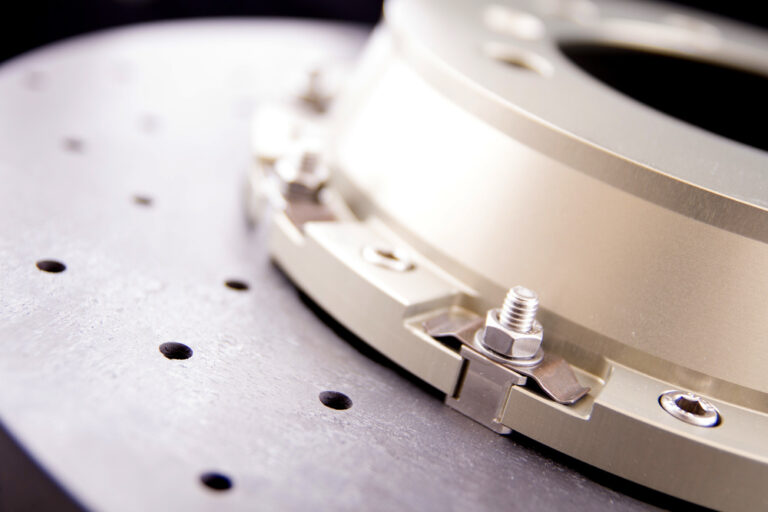

Surface Transforms plc (LON:SCE) are experts in the development and production of carbon-ceramic materials and the UK’s only manufacturer of carbon-ceramic brakes for automotive use.