Surface Transforms is sharpening its focus on OEM opportunities with a patented carbon-ceramic braking system that offers clear advantages in performance, weight and durability. The company’s Carbon-Silicon Carbide (CSiC) material is produced using in-house processes that convert Carbon-Carbon into a next-generation composite, aimed squarely at premium automotive manufacturers.

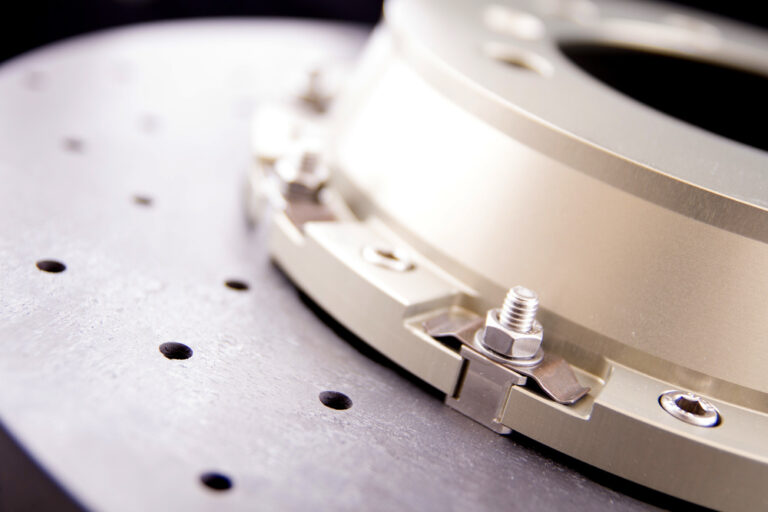

Where most production carbon-ceramic brakes use chopped carbon fibre, Surface Transforms applies continuous fibre in a 3D woven structure. The result is a stronger disc with triple the thermal conductivity of conventional options. This directly reduces brake system temperatures, keeping performance stable even under high stress.

Surface Transforms’ brake discs are up to 70% lighter than iron equivalents, cutting around 20kg of unsprung weight per vehicle. That translates to improved acceleration, sharper handling and greater efficiency—key metrics in both electric and combustion platforms. The technology also cuts brake wear, resists corrosion and delivers full performance even when cold, making it suitable for both track and road use.

Surface Transforms plc (LON:SCE) are experts in the development and production of carbon-ceramic materials and the UK’s only manufacturer of carbon-ceramic brakes for automotive use.