Surface Transforms plc (LON:SCE) manufacturers of carbon fibre reinforced ceramic automotive brake discs, has announced that the Company has received London Stock Exchange’s Green Economy Mark.

The award, first introduced in 2019, was created to highlight companies and investment funds listed on all segments of the market that are driving the green economy. To qualify for the Green Economy Mark, companies and investment funds must generate 50% or more of their total annual revenues from products and services that contribute to the global green economy. The award recognises both “pure-play” green technology companies, as well as those across all industries that are making a significant contribution to the transition to a sustainable low carbon economy. Only 108 of all London listed companies have qualified for the award.

Kevin Johnson, Surface Transforms CEO said: “We are delighted to receive this recognition. We are proud that our technology is assisting the reduction in the carbon footprint of the automotive industry, through engine emissions (lighter weight), accelerating the use of electric vehicles and reduced brake pad dust. These issues have long been of crucial importance to our customers and we are now increasingly seeing the same focus from investors. Our work on ESG will remain central to how we continue to develop the Company.”

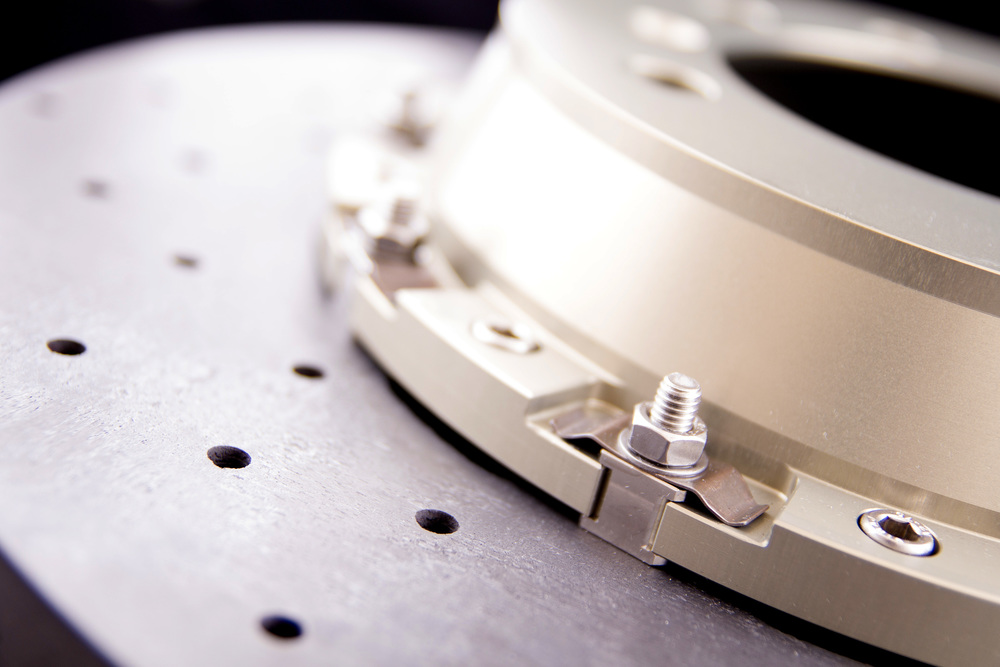

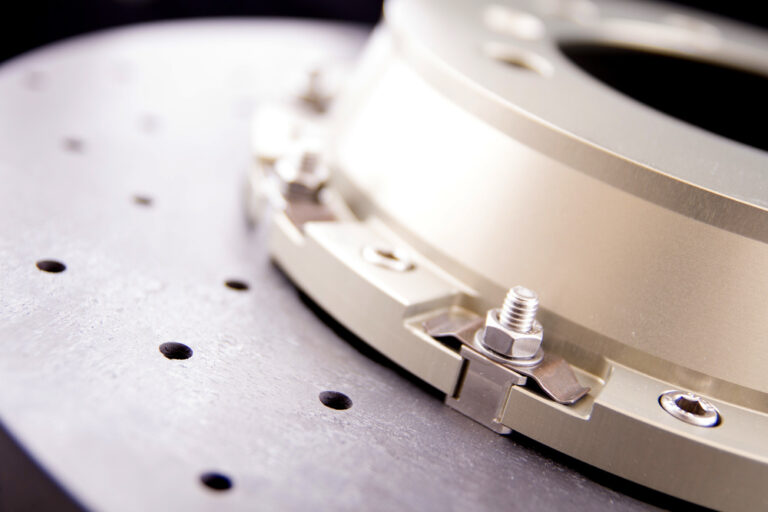

Surface Transforms plc. (LON:SCE) develops and produces carbon‐ceramic material automotive brake discs. The Company is the UK’s only manufacturer of carbon‐ceramic brake discs, and only one of two mainstream carbon ceramic brake disc companies in the world, serving customers that include major OEMs in the global automotive markets.

The Company utilises its proprietary next generation Carbon Ceramic Technology to create lightweight brake discs for high‐performance road and track applications for both internal combustion engine and electric vehicles. While competitor carbon‐ceramic brake discs use discontinuous chopped carbon fibre, Surface Transforms interweaves long strand carbon fibre to form a 3D matrix, producing a stronger and more durable product with improved heat conductivity compared to competitor products; this reduces the brake system operating temperature, resulting in lighter and longer life components with superior brake performance. These benefits are in addition to the benefits of all carbon‐ceramic brake discs vs. iron brake discs: weight savings of up to 70%, longer product life, consistent performance, reduced brake pad dust and corrosion free.