Carbon ceramic brake systems are engineered for extreme conditions, offering low weight, high heat resistance and minimal wear. For decades they remained a high-cost, high-performance feature, reserved for supercars and motorsport. That is changing. Suppliers across the value chain are seeing new demand signals as the material begins to filter into broader OEM and aftermarket use.

Carbon ceramics outperform traditional iron discs in every key metric that matters to modern vehicle platforms, weight, durability and efficiency. For electric vehicles, that means lower unsprung mass and improved range. For premium SUVs and sports saloons, it offers consistent braking under heavy loads without fade. For fleet buyers, the long replacement cycle offsets the higher upfront cost.

More importantly, the technology is evolving. New manufacturing techniques are reducing cost barriers and allowing for more modular applications. Some suppliers are adapting formulations to suit non-luxury applications, including performance variants of EVs and next-generation hybrids.

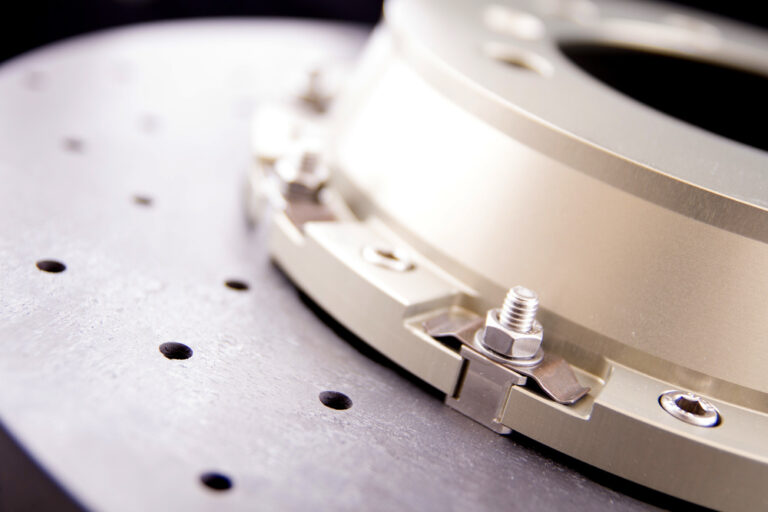

Surface Transforms plc (LON:SCE) are experts in the development and production of carbon-ceramic materials and the UK’s only manufacturer of carbon-ceramic brakes for automotive use.