Carbon ceramic brakes are no longer limited to supercars and track-focused models. Their use is expanding across a wider range of vehicles, driven by the need for durability, lower maintenance, and long-term cost efficiency. This shift is opening up a broader opportunity that may not yet be fully priced into supply chains or automotive investment strategies.

These brakes last significantly longer than traditional steel options and are far more resistant to heat and wear. In passenger cars used for towing, SUVs designed for heavier loads, or emergency response vehicles where downtime must be minimised, the benefits are clear. For electric vehicles, where regenerative braking reduces mechanical brake use, carbon ceramic systems provide additional value by lasting longer and staying cooler under repeated loads.

Cost has historically been a barrier, but that picture is starting to change. Manufacturers are now developing hybrid versions and refining production processes to bring down prices. The result is that carbon ceramic systems are being considered not just for top-end models but for vehicles where reliability, performance consistency, and reduced servicing are becoming critical design factors.

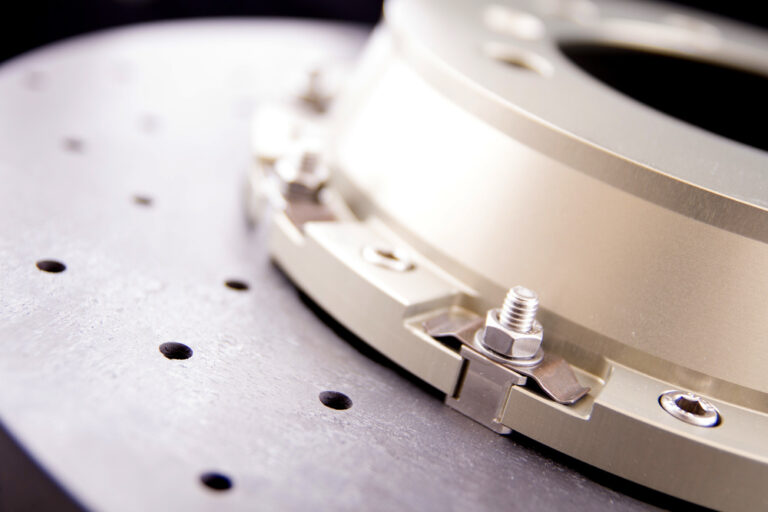

Surface Transforms plc (LON:SCE) are experts in the development and production of carbon-ceramic materials and the UK’s only manufacturer of carbon-ceramic brakes for automotive use.