In recent years, braking systems have moved far beyond their traditional safety function to become a domain of strategic innovation. As vehicle designs lean increasingly towards high-performance platforms—whether for sport, utility, or electric applications—the role of advanced braking has evolved into a significant brand and margin lever. This shift is not being driven by regulation or standardisation but by competition and consumer expectation, particularly at the premium end of the market.

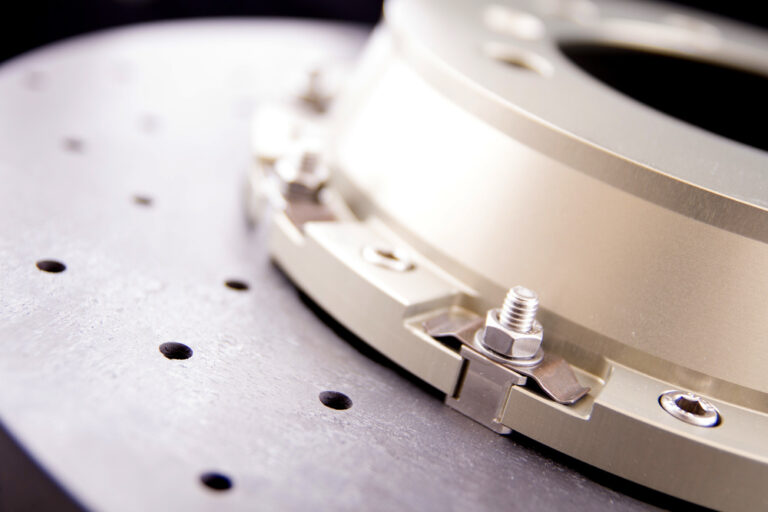

A central trend within this evolution is the rise of performance brake kits. These modular systems offer an upgrade path that goes well beyond aesthetics, delivering measurable improvements in thermal resistance, fade reduction, and stopping power. By adopting multi-piston calipers, slotted or drilled rotors, and advanced pad compositions, manufacturers are enabling superior braking performance under repeated load cycles—a core differentiator for both track-oriented drivers and increasingly demanding daily users. These kits are no longer reserved for aftermarket enthusiasts; they are being factored into original manufacturing and premium trim strategies to enhance perceived and actual value.

Simultaneously, materials innovation is opening up a new competitive front. Carbon-ceramic brakes, once the preserve of exotic supercars, are trickling down into more accessible segments thanks to manufacturing advances and cost rationalisation. These lightweight, heat-tolerant systems offer dramatic gains in both braking consistency and unsprung mass reduction—attributes that tie directly into energy efficiency and range performance for electric vehicles. What makes this noteworthy from an investment perspective is not simply the product’s appeal but its impact on broader platform economics. Lighter braking systems translate to less wear on suspension, smoother handling dynamics, and—critically—better battery performance in EVs.

The market dynamics around brake system upgrades also mirror broader shifts in consumer behaviour. Enthusiast buyers are increasingly prioritising performance integrity over raw horsepower, especially in the era of electrification where acceleration alone no longer differentiates. Braking, traditionally a reactive feature, is now being rebranded as a proactive choice—a statement of driving intent. This makes it an ideal focus area for brands seeking to cultivate loyalty through engineering depth rather than marketing gloss.

There is also a strong aftermarket signal worth noting. Retrofit kits and component upgrades remain a high-margin, low-barrier entry point into brand ecosystems, allowing OEMs and third-party suppliers alike to monetise customer enthusiasm long after the initial sale. As subscription models and digital customisation evolve, hardware upgrades such as brake kits could become a critical bridge between physical product and ongoing revenue streams. In this context, braking systems are no longer a closed chapter once a vehicle rolls off the line; they are part of a continuous engagement strategy.

Crucially, brake technology is becoming a testing ground for cross-sector collaboration. Material science firms, data analytics specialists, and component manufacturers are converging to deliver smarter, more adaptive braking systems that communicate with the broader vehicle ecosystem. Predictive wear analytics, real-time thermal mapping, and regenerative coordination are no longer theoretical—they are being quietly embedded into next-generation platforms. For investors, this opens the door to strategic exposure not only in automotive manufacturing but also in adjacent industries where brake system innovation has downstream relevance.

The shift from traditional hydraulic systems to electronically modulated braking also underscores the sector’s readiness for further automation. As autonomous driving advances, braking must become more precise, more reliable, and more integrated with onboard systems. The companies that master this orchestration—blending sensor input, AI logic, and mechanical response—stand to gain a durable advantage not just in performance, but in trust. And in a world where machine decisions may soon replace human ones, trust in fundamental functions like braking becomes the ultimate brand currency.

The transformation of brake technology represents more than just a product upgrade. It reflects a convergence of consumer demand, materials engineering, and digital integration that could meaningfully influence long-term brand equity and unit economics. For investors looking beyond short-cycle trends, this underappreciated corner of the vehicle is fast becoming a place where lasting value is built.

Surface Transforms plc (LON:SCE) are experts in the development and production of carbon-ceramic materials and the UK’s only manufacturer of carbon-ceramic brakes for automotive use.