Surface Transforms is the only company in the UK that manufactures carbon-ceramic brake discs. The company’s full control over its production process gives it a structural advantage in a market where quality, safety and scale are increasingly under scrutiny.

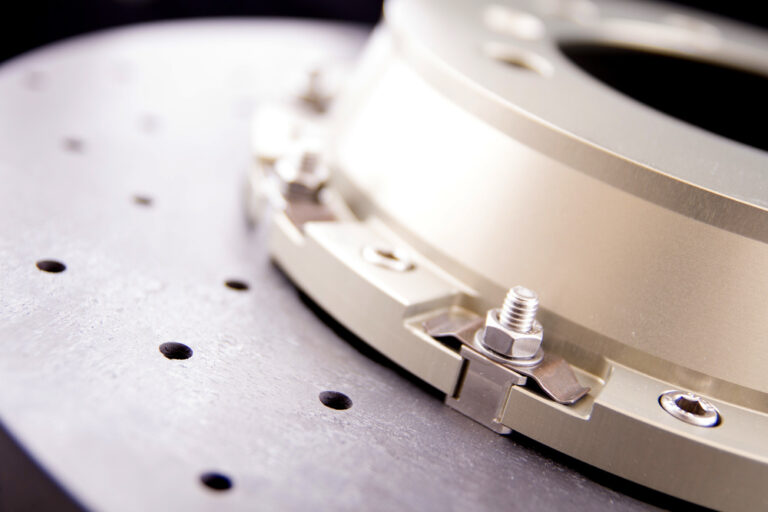

Its brake discs begin as layers of carbon-fibre cloth, built into a 3D shape known as a preform. These are then heat-treated in high-temperature furnaces to remove impurities and create a strong carbon base. From there, the company applies its proprietary chemical vapour infiltration method, bonding the carbon with a ceramic matrix. A separate melt-infiltration stage adds silicon carbide, a material known for its thermal stability and hardness. These steps are followed by precision machining, a self-healing anti-oxidation coating and a final inspection to confirm tolerances and durability.

What makes Surface Transforms stand out is that all of this is done in-house at its Merseyside facility. This level of vertical integration is rare in the carbon-ceramic brake sector and gives the company more control over cost, quality and delivery. It also means Surface Transforms is not dependent on overseas supply chains for critical process steps, an advantage as automotive OEMs look to de-risk procurement and localise key components.

Surface Transforms plc (LON:SCE) are experts in the development and production of carbon-ceramic materials and the UK’s only manufacturer of carbon-ceramic brakes for automotive use.