The European market for carbon-ceramic braking systems is becoming a meaningful axis of value in performance vehicle engineering. What was once reserved for ultra-rare supercars is now filtering into premium EVs, sport SUVs and high-margin saloons, unlocking a surprisingly durable stream of opportunity for investors. At the heart of this lies a simple equation: less weight, more control, and longer life, all delivered without compromising aesthetics or driver feel.

This isn’t about gimmicks. Carbon-ceramic brakes reduce unsprung mass by as much as 70 per cent compared to iron discs. That reduction significantly sharpens handling, increases efficiency, and allows braking systems to perform with consistent precision under prolonged thermal stress. The result is not just faster lap times, but tangible gains in safety, wear resistance, and ride comfort, qualities increasingly valued as vehicles become heavier and more digitally integrated.

Europe’s positioning here is no accident. Regulatory demands around emissions and road safety are pushing OEMs to extract more performance from less. Braking systems that offer durability, reliability and weight reduction naturally align with these priorities. As electrification accelerates, the weight of battery systems further reinforces the case for lighter components. Carbon-ceramic brakes meet that challenge while also enhancing vehicle dynamics, a win for engineers and a quiet signal to the market.

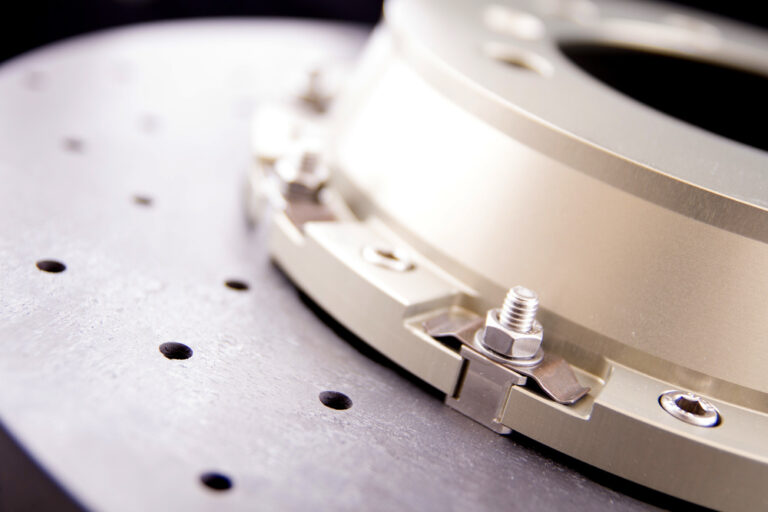

The engineering edge is reinforced by deep materials science innovation. Manufacturers are evolving beyond standard composites to deploy continuous-fibre ceramic matrices, enhancing thermal conductivity and enabling remanufacturing of worn discs. This not only extends product life but introduces a sustainability narrative that aligns with shifting consumer expectations. For investors, that’s a rare double—environmental logic matched by cost advantages and long-term supply potential.

Technical evolution doesn’t stop at the material level. Embedded sensors are now being integrated directly into braking systems to monitor wear, temperature, and stress in real time. This feeds directly into the connected vehicle ecosystem, where predictive maintenance and lifecycle optimisation are becoming monetisable features. As these systems mature, braking components transform from inert hardware into smart, responsive elements of a broader data-driven vehicle architecture.

Commercially, the shift is already underway. European suppliers are scaling production capacity in anticipation of growing OEM demand across multiple tiers, not only hypercars but also mainstream performance lines where carbon-ceramic adoption is set to expand. What once counted as exotic is becoming a value-adding differentiator in more accessible segments. For component makers, that suggests scale economies and rising contract visibility, even as price points normalise.

There’s also a meaningful aftermarket dynamic at play. As carbon-ceramic systems migrate into more widely sold models, replacement cycles and upgrade paths grow deeper. Luxury owners seeking to refresh performance without replacing their vehicle entirely are turning to upgraded discs and calipers, a trend that quietly bolsters margins for suppliers focused on longevity and precision fitment.

While global demand is rising, Europe retains a strategic advantage. Its density of performance OEMs, regulatory cohesion, and consumer appetite for premium features position it as the natural innovation hub in this space. Investors tracking composite materials, sensor integration, or premium vehicle components would be wise to assess which firms are capturing this migration from high-end option to embedded standard.

The broader implication is that carbon-ceramic braking systems are no longer a statement of excess, they’re becoming a foundational component of modern high-performance mobility. For investors, that signals something more enduring than aesthetic appeal or brand cachet. It points to a convergence of weight reduction, data integration, and regulatory alignment that quietly but significantly underwrites long-term positioning for a small group of high-potential suppliers.

Surface Transforms plc (LON:SCE) are experts in the development and production of carbon-ceramic materials and the UK’s only manufacturer of carbon-ceramic brakes for automotive use.