As power outputs rise and driver expectations shift, components like pads, discs, and callipers are playing a larger role in how vehicles perform under real-world and track conditions. This is opening up new commercial relevance for firms that supply or upgrade these parts.

The contrast between standard and performance brake pads now extends beyond feel and fade resistance. Different compounds directly affect stopping consistency, wear rates, and heat management. For owners of high-performance models, this has become a critical factor in driving satisfaction and maintenance planning. The ability to handle repeated high-speed stops without loss of pedal response is now essential, particularly in vehicles that are increasingly dual-purposed for both road and track use.

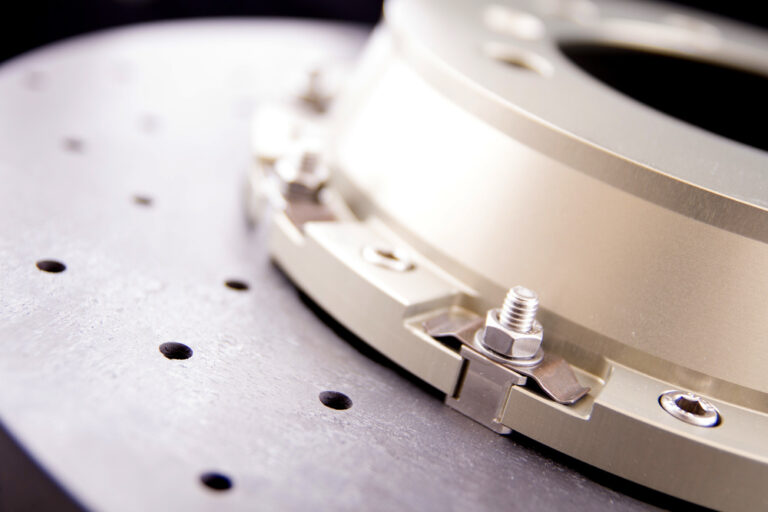

Big brake kits are another area where demand is growing. These upgrades typically include larger rotors and stronger callipers designed to cope with more aggressive driving. They deliver more stable braking under load, reduce fade, and extend component life.

Surface Transforms plc (LON:SCE) are experts in the development and production of carbon-ceramic materials and the UK’s only manufacturer of carbon-ceramic brakes for automotive use.