Surface Transforms is no stranger to the challenges of commercialising advanced materials. As a specialist in carbon-ceramic brake discs, the company operates at the intersection of automotive performance, aerospace reliability, and motorsport innovation.

Historically, Surface Transforms had relied on disparate tools to manage quality documentation, audits, and employee training. Documents lived on shared drives, with manual sign-offs and limited traceability. This system was fragile, especially as production volumes rose and customer expectations — particularly from Tier 1 and OEM clients, demanded more rigour. Recognising this, the company introduced a unified quality management system that has fundamentally reshaped its operational backbone. Training compliance is now automated with role-based matrix alerts, document control is centralised and version-controlled, and the shop floor has moved towards a paper-free environment.

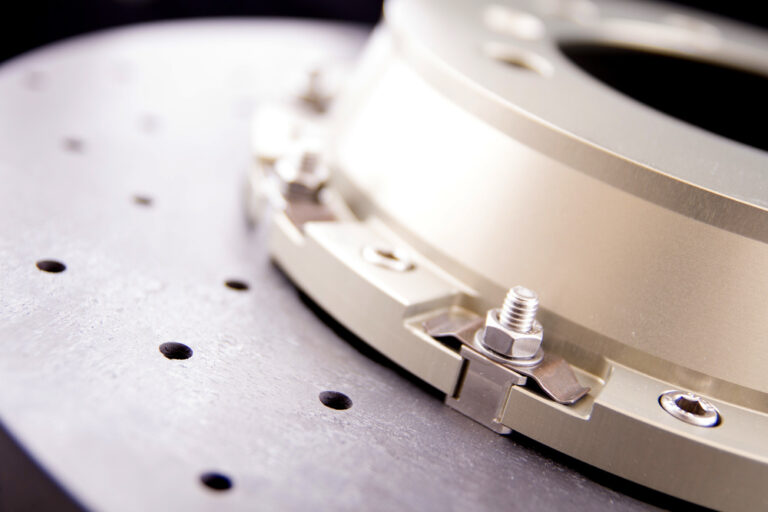

Surface Transforms has developed a proprietary process that addresses one of the legacy issues with carbon-ceramics: thermal management and rotor cracking. Their continuous-fibre, 3D-woven structure and unique treatment methodology provide improved resistance to heat stress, giving them a competitive edge when pitching to OEMs in premium and electric segments. As electric vehicle weight continues to rise, brake performance and weight trade-offs become increasingly relevant.

Surface Transforms plc (LON:SCE) are experts in the development and production of carbon-ceramic materials and the UK’s only manufacturer of carbon-ceramic brakes for automotive use.