Great Western Mining Corporation plc (LON:GWMO), a strategic minerals exploration and development company, has announced assay results from a machine-cut channel sampling programme at its Defender Tungsten Project in Mineral County, Nevada USA.

HIGHLIGHTS

· Two machine-cut channels completed in December 2025 at Defender returned significant tungsten mineralisation:

o Channel A intercepted 6 m (20ft) @ 0.17% WO3, including 1 m (3ft) @ 0.43% WO3 (Table 1).

o Channel B intercepted 16 m (52ft) @ 0.30% WO3, including 2 m (7ft) @ 0.66% WO3 (Table 1).

· Very low concentrations of potential penalty elements encountered during WO3 processing (Table 1).

· Silver (Ag) mineralisation found in Channel B, with 2 m (6.5ft) @ 2.95 g/t Ag in the garnet skarn and 3 m (10ft) @ 1.55 g/t Ag in granite.

Great Western Chairman Brian Hall commented: “In a rapidly changing world in which tungsten has become a critical metal for defence and industrial use, currently in short supply in the West, the confirmation of significant mineralisation at Defender is a very exciting development for Great Western. This initial channel sampling operation has confirmed the presence of tungsten, which was previously indicated by soil and rock chip sampling last year, with results firmly at the upper end of our expectations. Notably, minerals that could impair processing such as molybdenum and lead were immaterial in the results. We are now planning the next stages and will keep shareholders informed.”

DETAILS

Background

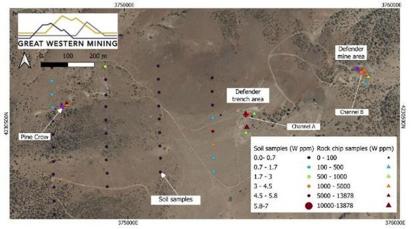

The Defender and Pine Crow tungsten skarns, which produced tungsten during World War II, lie approximately 2 km northeast of and on trend with the Company’s M2 skarn copper resource. All these skarns occur at the contact zones of Cretaceous granitic intrusions with limestones of the Jurassic Dunlap Formation. Field mapping and grab sampling reported in June 2025 confirmed scheelite-bearing skarns at both Defender and Pine Crow, with rock chip samples recording up to 1.75% tungsten trioxide (WO3) (see RNS dated 16 June 2025). Soil sample geochemistry from the Defender and Pine Crow area shows elevated tungsten, copper and zinc, which can be traced for at least 1.4 km along strike following a granite-limestone contact, indicating extensions to the outcropping skarn-style mineralisation at Pine Crow and Defender (see RNS dated 27 October 2025).

Channel sampling

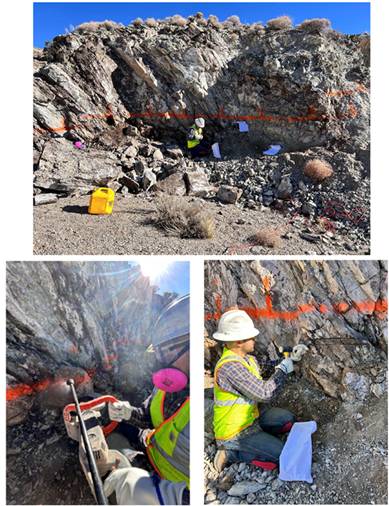

In December 2025, two channels were machine-cut to assess mineralisation by collecting samples at 1 m intervals. Channel A was excavated across an existing trench, while Channel B was cut across historic surface workings. Channel start and end co-ordinates were measured by handheld GPS and the channels measured by chain survey. All samples were submitted to American Assay Laboratories, Sparks, Nevada.

The samples were analysed by ICP-OES and ICP-MS after both four acid-digest (4AD) and sodium peroxide fusion digestion (methods IM-4AB52 and IO-NF43). Quality control samples (duplicates, blanks, and certified reference materials) were inserted by the Company and results reviewed prior to release.

The trenching programme delivered strong tungsten results from both channels. Channel A returned 6 m (20ft) at 0.17% WO₃, including a high-grade interval of 1 m (3ft) at 0.43% WO₃. Channel B produced an even stronger result of 16 m (52ft) at 0.30% WO₃, including 2 m (7ft) at 0.66% WO₃ (Table 1).

Channel B also demonstrated silver mineralisation, intersecting 2 m (7ft) at 2.95 g/t Ag within garnet skarn and 3 m (10ft) at 1.55 g/t Ag within granite. Importantly, elements that could act as processing penalties for WO₃ were recorded at very low concentrations (Table 1).

These results, supported by grab samples and a complete set of fully assayed soils, including those collected in Spring 2025 but not previously analysed, will be used to guide the next phase of exploration.

Figure 1: Map showing the location of the two machine-cut channels at Defender and previously reported W (ppm) soil and rock chip samples. Coordinates in EPSG 26911.

|

Figure 2: Meter sections across the outcropping skarn were surveyed, cut, collected and bagged.

Table 1: Highlight channel sample assay intervals.

| Channel | From (m) | To (m) | Interval (m) | Lithology | WO3% * | Ag g/t | Cu ppm | Mo ppm | Zn ppm | Includes |

| A | 11 | 17 | 6 | Scheelite bearing garnet skarn | 0.17 | 0 | 72 | 100 | 186 | 1 m @ 0.43% WO3 |

| B | 2 | 18 | 16 | Scheelite bearing garnet skarn | 0.30 | 0.38 | 70 | 127 | 323 | 2 m @ 0.66% WO3, 1m @ 0.55% WO3 and 2 m @ 2.95 g/t Ag |

| B | 21 | 22 | 1 | Scheelite bearing garnet skarn | 0.38 | 0 | 8 | 208 | 161 | |

| B | 22 | 25 | 3 | Granite | 0.04 | 1.55 | 74 | 22 | 120 |

*W ppm converted to WO3% by stoichiometric calculation.