Carbon ceramic brake discs, once confined to supercars and the occasional race circuit, are redefining what durability and performance mean in modern mobility. What started as an indulgence for enthusiasts has become a material science story shaping the next generation of vehicles, from electric sedans to long-haul fleets.

Traditional steel rotors, efficient under light load, falter under continuous strain. The sensation of fading brakes on a steep descent is the result of heat distortion and loss of friction. Carbon ceramics, by contrast, remain composed. Formed from carbon fibre reinforced with ceramic compounds, these discs maintain structural integrity at temperatures that would buckle steel.

Shedding nearly half the mass of comparable steel rotors, carbon ceramics reduce unsprung weight, sharpening steering feedback and improving ride quality. In performance cars, that translates to faster response; in electric vehicles, it helps conserve battery range by easing mechanical load.

Brands from Porsche and Ferrari to Tesla and Lucid now use carbon ceramic systems to manage the thermal complexity of high-performance and high-efficiency drivetrains. In heavy-duty and fleet applications, the same resilience translates into fewer service intervals and lower long-term operating costs. As regulatory attention turns to brake emissions and particulate reduction, their low-dust characteristics add another layer of relevance.

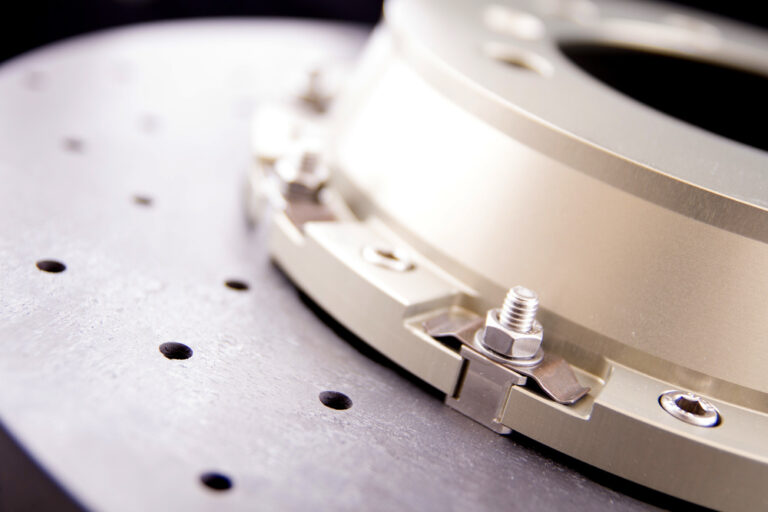

Surface Transforms plc (LON:SCE) are experts in the development and production of carbon-ceramic materials and the UK’s only manufacturer of carbon-ceramic brakes for automotive use.