Surface Transforms plc (LON:SCE), manufacturers of carbon fibre reinforced ceramic brake discs, has reminded shareholders of its Annual General Meeting (AGM) to be held today, Thursday 30 June 2022 at 11:00 a.m. at the offices of finnCap, 1 Bartholomew Close, London, EC1A 7BL.

Following the conclusion of the AGM, at approximately 11.15 a.m., Kevin Johnson, (CEO), will provide a presentation on both sales and operations progress. A separate and more detailed trading update for H1-2022, including half-year sales and cash numbers, will be provided before the overspill Capital Markets Day on 7 July.

Within the presentation, Kevin Johnson will advise that following communication from OEM 8 on an imminent start of production (SOP) delivery date and subsequent series delivery schedules, the Company has now commenced series production. In light of this news, and in addition to continuing deliveries to all its other significant customers, the Board is pleased to restate the guidance provided in the Chairman’s report in the 2021 preliminary results; “The Company continues its journey to profitability in 2022 and remains confident that this goal will be achieved, whilst maintaining our commitment to environmental and social goals.”

The presentation will also be available on the Surface Transforms website: www.surfacetransforms.com after the conclusion of the meeting.

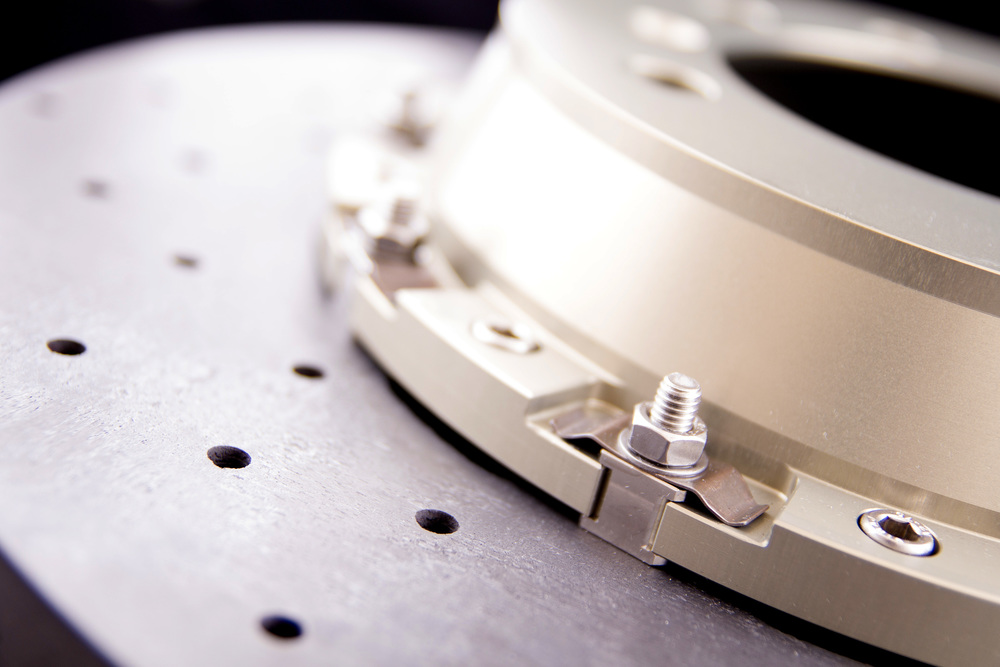

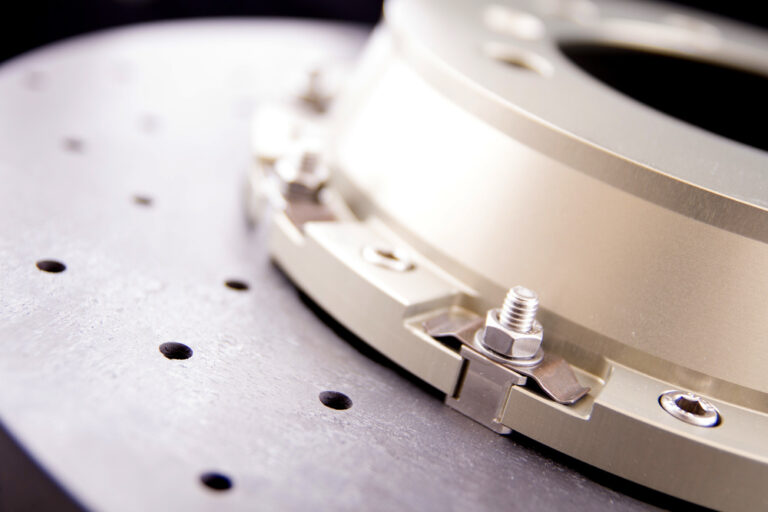

Surface Transforms plc. develop and produce carbon‐ceramic material automotive brake discs. The Company is the UK’s only manufacturer of carbon‐ceramic brake discs, and only one of two mainstream carbon ceramic brake disc companies in the world, serving customers that include major OEMs in the global automotive markets.

The Company utilises its proprietary next generation Carbon Ceramic Technology to create lightweight brake discs for high‐performance road and track applications for both internal combustion engine and electric vehicles. While competitor carbon‐ceramic brake discs use discontinuous chopped carbon fibre, Surface Transforms interweaves continuous carbon fibre to form a 3D matrix, producing a stronger and more durable product with improved heat conductivity compared to competitor products; this reduces the brake system operating temperature, resulting in lighter and longer life components with superior brake performance. These benefits are in addition to the benefits of all carbon‐ceramic brake discs vs. iron brake discs: weight savings of up to 70%, longer product life, consistent performance, reduced brake pad dust and corrosion free.