Ilika plc (LON:IKA) Chief Executive Officer Graeme Purdy caught up with DirectorsTalk for an exclusive interview to discuss how Stereax batteries are made, the pilot line operation, key factors that resulted in outfitting and operating its own facility and the timeline involved.

Q1: Update this morning regarding Ilika’s is manufacturing plans for Stereax, could you just briefly describe the process for making these batteries?

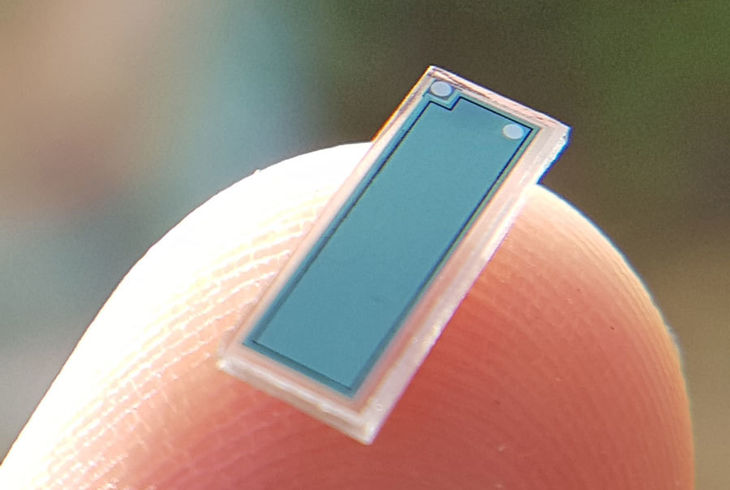

A1: Our Stereax batteries are miniature batteries which are used to power miniature medical devices and internet of things for industry so wireless sensors in hostile environments in particular. These batteries are made on wafers and they’re deposited in a vacuum deposition process, similar to the processes that are used by the MEMS industry to make sensors and actuators. Once we’ve deposited the active materials onto the wafers, then they’re processed using microfabrication techniques which effectively allow us to pattern the wafers and make the individual devices.

Q2: Can you recap on the status of your pilot line operation then?

A2: So, at the moment, these Stereax miniature cells are made on a pilot line that is located in facilities which are within the university of Southampton here in the UK. We are at the point where the utilisation of that pilot line for commercial sales has justified us raising the capital to invest in a manufacturing facility. So, we’re at an exciting point in scaling up that technology.

Q3: Now, you previously talked about having a third party facility or fab run the scale-up process for you. What sort of fabs did you consider?

A3: We’ve looked at mid-sized fabs around the world, most of the suitable facilities would either be in North America or Europe, typically historically semiconductor fabs which are designed to run a six inch or maybe eight inch wafers. Most recently, most of them have specialised in producing MEMS devices, these sensors.

Actually, we’ve compared these facilities with the option of the company outfitting its own facility close to our current operating base here in Southampton.

Q4: And you’ve decided now to outfit your own operating facility, what were the key factors that resulted in this?

A4: Well, when we’ve looked at these different options, we’ve always wanted to maximise the return on investment that we’re making, it’s quite a sizeable investment, about £4 million relative to the size of the company, and we want to make sure that we get this right.

So, we’ve always looked for the route that gets us to market quickest, what’s the option that has the quickest route to product launch and also, increasingly actually over the past year, we’ve become sensitive to control of our own implementation timelines and operations without having to worry about any restrictions or other priorities that a third party might have.

Ultimately, we’ve been very sensitive to ensuring that we’ve got an attractive operating margin at volume production to ensure that we’ve got profitable products that we bring to market. In terms of managing the risk of the implementation, we’ve always wanted to make sure that we’ve got sufficient access to the expertise that we’ve got in the core technical team.

Q5: Now, you’ve said that time is a factor, what is the implementation status and the timeline involved?

A5: The key pieces of equipment that Ilika need to implement this process are on order, one of the key bits of equipment is coming from the US and one of them is coming from Switzerland.

Fabrication of these equipment items is on track and we’re looking to outfit the facility that we’ve selected in Q1 of next year so that by the time we get into Q2, we can take delivery of these equipment items, commission them, put them through their initial process qualification and then start our product qualification process.

So, we’re very much looking forward to the seventy-fold increase in productivity that we can expect from this implementation by the time we get to the end of 2021.