Surface Transforms, a specialist in advanced materials and high-performance braking systems, is emerging as a pivotal player in the automotive industry’s push towards lighter, more durable, and high-efficiency components. At the core of this momentum is the company’s proprietary carbon-ceramic brake disc technology, a solution that not only outperforms traditional cast iron and competitor ceramic brakes but also offers significant long-term cost and environmental benefits.

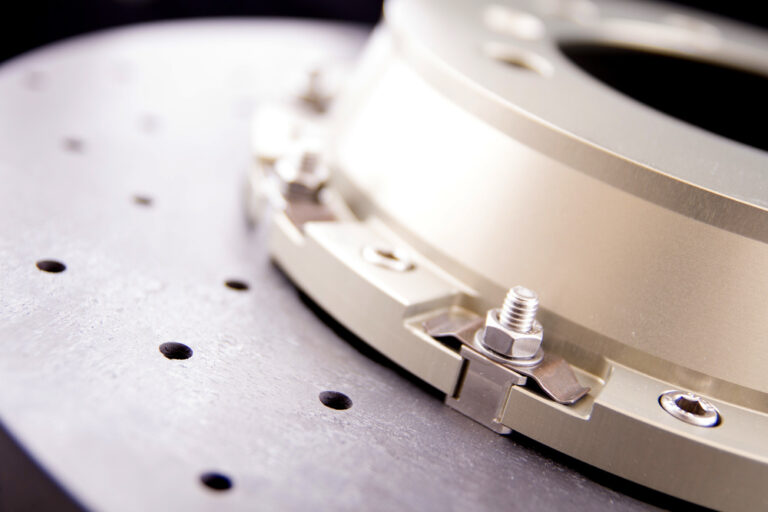

What sets Surface Transforms apart is its unique manufacturing process, which re-engineers the internal structure of carbon-ceramic materials. Unlike other ceramic brakes, which typically use chopped or discontinuous fibres, Surface Transforms employs a continuous fibre matrix. This dramatically improves thermal conductivity and resistance to cracking, two of the biggest limitations in legacy ceramic disc technologies. The result is a brake disc that operates cooler, lasts longer, and performs more reliably under the most extreme conditions—qualities highly sought after in both supercar and motorsport applications.

As the automotive sector pivots towards electrification and lightweight engineering, the relevance of Surface Transforms’ offering only intensifies. With electric vehicles (EVs) placing new demands on braking systems due to regenerative braking and increased vehicle mass, the need for high-performance, low-weight solutions becomes critical. Surface Transforms’ discs are up to 70% lighter than conventional alternatives and provide enhanced stopping power with reduced brake fade, making them ideally suited to the new generation of high-performance EVs.

The company’s recent traction with original equipment manufacturers (OEMs) further validates its commercial potential. Surface Transforms has already secured multi-million-pound contracts with several leading supercar and hypercar manufacturers. These relationships are not merely testaments to product quality but also signal the scalability and manufacturability of its offering. As production volumes increase, economies of scale are expected to drive margin expansion, while growing OEM adoption will provide long-term revenue visibility.

In addition to automotive OEMs, Surface Transforms is extending its reach into aerospace, military, and industrial sectors. The properties of its carbon-ceramic materials, such as weight reduction, heat resistance, and corrosion durability, offer compelling advantages for aircraft brakes, rotorcraft, and high-speed rail. This multi-industry applicability opens up a broader addressable market and provides resilience against the cyclical nature of automotive production.

Behind the scenes, the company is continually refining its proprietary manufacturing techniques. Its vertically integrated process ensures full control over quality and consistency, while also allowing the flexibility to meet bespoke requirements from customers. Surface Transforms is not standing still; its R\&D efforts are focused on increasing throughput, automating production steps, and enhancing cost-efficiency, key drivers that will underpin future competitiveness.

Investor sentiment is likely to be buoyed by the combination of technological edge, expanding order book, and growing sector tailwinds. As vehicle manufacturers worldwide race to optimise every gram of weight and every degree of performance, Surface Transforms finds itself in an enviable position, delivering a product that is not only superior but essential for next-generation mobility.

Surface Transforms plc (LON:SCE) is a manufacturer of next-generation carbon-ceramic brake discs for automotive and aircraft applications and has been certified to IS9001-2000 since 2008 and was certified to TS16949 automotive quality accreditation and AS9100C aerospace quality accreditation in 2015.