The luxury vehicle and supercar market is undergoing a significant transformation. What was once a realm dominated purely by aesthetics and badge prestige is now laser-focused on performance, engineering refinement, and cutting-edge technology. One component driving this evolution is the carbon ceramic brake, lightweight, durable, and offering superior heat resistance under extreme stress.

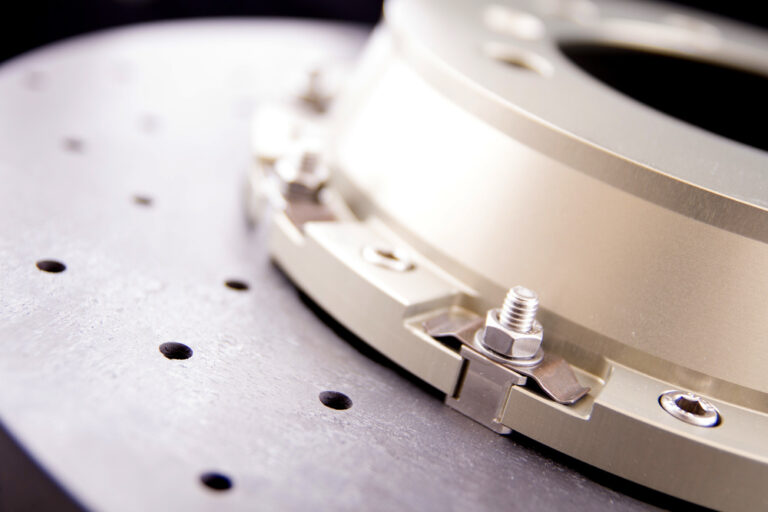

In elite automotive engineering, performance is non-negotiable. Supercars, hypercars, and the latest generation of luxury sedans are pushing limits not just in acceleration but also in precision control. At the heart of this capability is braking technology that must withstand the same levels of intensity as motorsport-grade systems. Carbon ceramic brakes offer unmatched stopping power with reduced fade under high temperatures, lower unsprung weight, and vastly extended lifespans compared to traditional iron discs.

The rising penetration of this technology into production vehicles reflects both an engineering shift and a lifestyle statement. Manufacturers are no longer restricting carbon ceramic systems to limited-edition models. Instead, they’re becoming a selectable upgrade on a broader range of high-performance vehicles. This growing accessibility is fuelling a global surge in demand, one that is no longer confined to elite supercar makers but is spilling over into electric luxury vehicles and performance SUVs.

Surface Transforms is particularly well-positioned in this rapidly scaling market. As one of the few specialist manufacturers outside the traditional Tier 1 supplier ecosystem, it brings an innovative proprietary approach to carbon ceramic disc production. Unlike conventional processes which often involve outsourced or sintered technologies, Surface Transforms employs a continuous-fibre ceramic matrix composite. This offers enhanced performance characteristics while reducing environmental and operational costs, two factors that resonate strongly with the strategic goals of next-generation vehicle manufacturers.

The scalability of the technology is also key. As the market expands, manufacturers are seeking partners who can not only deliver elite performance but also meet volume requirements and cost targets. Surface Transforms has been investing heavily in expanding its production footprint, optimising automation, and refining quality assurance systems. These operational moves are not just about meeting today’s demand, they are about capturing tomorrow’s market share.

Investors eyeing the advanced automotive component sector are watching the brake segment closely. While carbon ceramic systems were once seen as exotic add-ons, they are now viewed as essential elements of a serious performance package. With electrification and hybridisation of performance cars gaining traction, braking systems must now cope with heavier vehicle weights and regenerative braking demands. This puts even greater emphasis on brake durability and thermal performance—=,criteria in which carbon ceramic technology excels.

The macro conditions are also favourable. Consumer interest in performance cars remains robust even amidst broader economic headwinds, driven by aspirational buying patterns, international wealth expansion, and a cultural emphasis on engineering excellence. Meanwhile, regulatory pressures are nudging manufacturers to reduce vehicle weight wherever possible,a key advantage of ceramic discs over their iron counterparts.

As OEMs look to differentiate themselves through performance, innovation, and sustainability, the value of high-tech braking systems will only climb. For Surface Transforms, this creates a multi-dimensional opportunity: strong market demand, technological differentiation, and expanding OEM relationships across the luxury and performance spectrum.

Surface Transforms plc (LON:SCE) is a manufacturer of next-generation carbon-ceramic brake discs for automotive and aircraft applications and has been certified to IS9001-2000 since 2008 and was certified to TS16949 automotive quality accreditation and AS9100C aerospace quality accreditation in 2015.