The automotive industry is on the brink of a braking revolution as carbon ceramic systems push past niche performance markets and begin gaining ground in premium passenger and electric vehicles. These high-performance braking systems, originally developed for aerospace and motorsport applications, are rapidly becoming a critical differentiator in modern automotive engineering, thanks to their lightweight construction, superior thermal resistance, and exceptional durability.

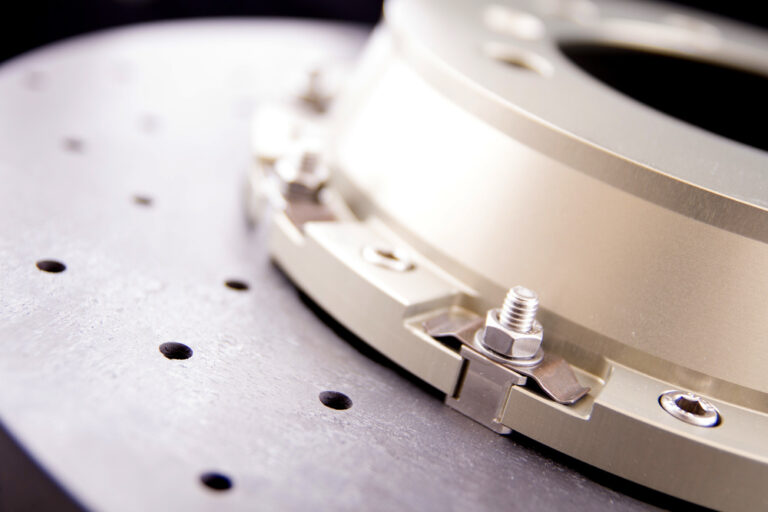

Carbon ceramic brakes are crafted using carbon fibres fused with ceramic materials, resulting in discs that are much lighter and significantly more durable than traditional iron alternatives. This weight reduction improves handling, acceleration, and energy efficiency, while their ability to maintain braking performance under extreme heat conditions makes them ideal for both high-speed and urban driving scenarios. This is especially relevant in electric vehicles where managing weight and extending range are key priorities.

Valued at around €244.8 million in 2023, the global carbon ceramic brake market is projected to reach €425.9 million by 2030, growing at a healthy annual rate of 7.6%. This expansion is driven by rising demand for high-performance and luxury vehicles, alongside tightening emission and efficiency regulations that are pushing manufacturers to adopt lighter, more durable components.

In addition to delivering reliable stopping power and reducing brake fade, carbon ceramic systems provide longer service life, cutting down on maintenance requirements and overall vehicle lifecycle costs. Their resistance to corrosion and thermal wear makes them highly attractive not just for sports cars, but increasingly for premium electric vehicles that benefit from weight savings and reduced energy consumption.

However, high manufacturing costs and complex production methods have long been barriers to mass adoption. These systems rely on costly raw materials like carbon fibre and silicon carbide, limiting their use to high-end segments. But ongoing research and technological advancements are making production more efficient, opening pathways to broader market accessibility. As these innovations continue, the automotive sector is preparing for a wider roll-out of carbon ceramic braking solutions across more vehicle classes.

Electric vehicle manufacturers are particularly well-positioned to benefit from this transition. The ability to reduce unsprung weight without sacrificing performance aligns perfectly with the engineering goals of EV makers looking to maximise range and handling precision. As the electric vehicle market expands, so too will the demand for advanced braking systems that support efficiency and long-term performance.

European automotive giants currently lead the charge in adopting carbon ceramic technologies, but emerging markets in Asia-Pacific are beginning to show significant potential as local manufacturers invest heavily in premium and electric vehicle development. This signals a promising growth trajectory that extends beyond traditional luxury markets.

Carbon ceramic brakes are redefining vehicle performance and setting new benchmarks for efficiency, safety, and durability. With manufacturing innovations driving costs down and market demand climbing, this technology stands poised to capture a much larger share of the automotive market in the years ahead.

Surface Transforms plc (LON:SCE) is a manufacturer of next-generation carbon-ceramic brake discs for automotive and aircraft applications and has been certified to IS9001-2000 since 2008 and was certified to TS16949 automotive quality accreditation and AS9100C aerospace quality accreditation in 2015.